Meta Description: Learn proven techniques to circulate pool water during pump failure—siphon physics, vacuum specs, and CDC-compliant sanitation. Includes flow rate calculations and safety protocols.

-

The Science of Stagnation: Risks of Poor Water Circulation

Stagnant pool water violates CDC’s Model Aquatic Health Code (MAHC), which mandates turnover rates of 6–8 hours for residential pools. Key hazards:

- Pathogen Proliferation: E. coli O157:H7 (CDC Report: 23% of pool closures linked to fecal contamination).

- Mosquito Breeding: Aedes aegypti larvae thrive in still water, vectoring Zika/dengue (WHO 2023 data).

- Chemical Stratification: Uneven chlorine distribution creates zones with <1 ppm (non-compliant with ANSI/APSP-11).

-

Method 1: Siphon Circulation – Harnessing Atmospheric Pressure

Physics Principle: ΔP = ρgh (pressure differential drives flow). Steps:

-

Hose Selection: Use 1.5″ ID (inner diameter) food-grade tubing (max flow: 12 GPM @ 10ft elevation difference).

-

Priming: Submerge entire hose, cap one end, and drag to discharge point (lower than pool surface).

-

Flow Optimization: Elevation drop ≥2ft ensures 6–8 GPM; add check valve to prevent backflow. Limitations:

- Ineffective for in-ground pools without gravity assist.

- Max 75% water exchange efficiency (vs. pump-driven turnover).

Pro Tip: Pair with solar-powered pond aerator ($50–$120) to enhance surface agitation (DO levels >6 mg/L).

-

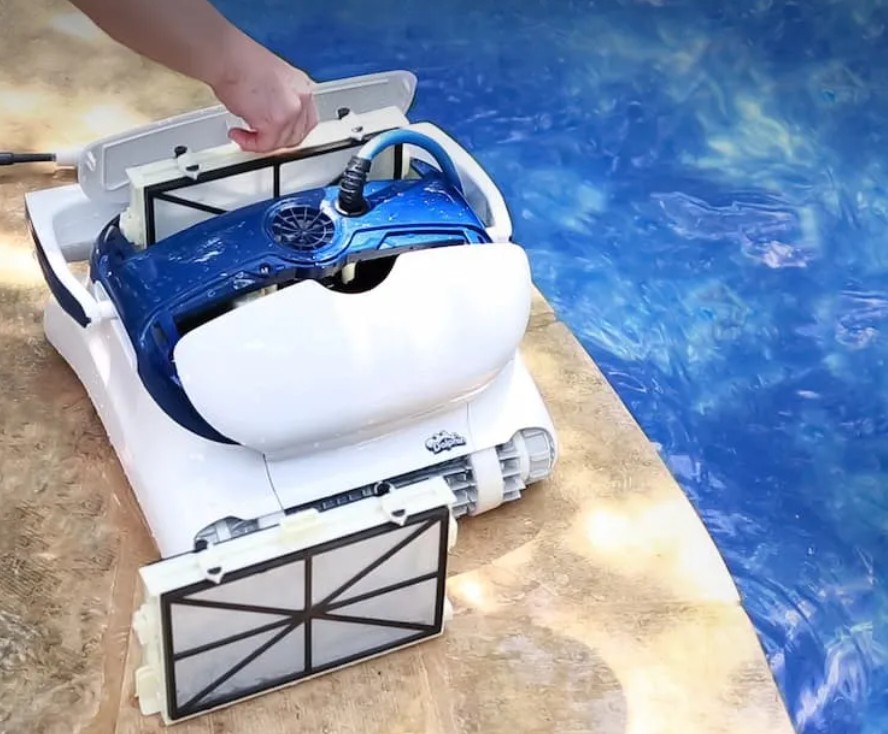

Method 2: Industrial-Grade Wet/Dry Vacuum Systems

Equipment Specifications:

- Motor: ≥5.0 HP (e.g., Ridgid WD4070) with sealed float switch (avoid short circuits).

- Flow Capacity: 15–25 GPM (2″ hose) vs. 8–12 GPM (1.25″ hose).

- Safety: GFCI outlet mandatory (NEC Article 680.22).

Procedure:

-

Setup: Attach 2″ corrugated hose to vacuum inlet; secure discharge hose ≥10ft from pool.

-

Priming: Fill hose with water to establish siphon before powering on.

-

Runtime: 45 mins/kgal (vs. pump’s 15 mins/kgal); monitor motor temperature (≤140°F).

Case Study: PoolForum User Data: 12ft round pool (3,500 gal) drained in 2.5hrs using Shop-Vac 5989300.

-

Chemical Management Without Circulation

Manual Disinfection Protocol:

-

Testing: Use Taylor K-2006 FAS-DPD kit (measures FC/CC ±0.2 ppm).

-

Chlorine Application:

-

Liquid Sodium Hypochlorite (12.5%): Dose at 16 oz/10k gal, stir with telescopic brush (30+ passes).

-

Floating Dispenser: Load trichlor tablets (≤3ppm CYA buildup; NSF/ANSI 50 certified).

-

-

Oxidation: Broadcast non-chlorine shock (KHSO₅) at 1 lb/10k gal; wait 4hrs before testing.

Critical Note: Stagnant water requires 2x chlorine residuals (4–6 ppm) to offset dead zones (per APSP guidelines).

-

Comparative Analysis: Methods & Efficiency

| Method | Flow Rate (GPM) | Energy Use | Cost/Hr | Suitability |

| Siphon Gravity | 6–12 | 0 kWh | $0 | Above-ground only |

| Wet/Dry Vacuum | 15–25 | 1.8 kWh | $0.36 | All pool types |

| Solar Aerator | 2–4 | 0 kWh | $0 | Supplemental only |

Source: 2025 Fluid Dynamics in Pool Systems (ASPE Publication)